Home / Technology / Logistics DX & Robotics

Designing integrated, efficient robot warehouse systems for stable and scalable automation

Automation technology and AI are generating significant attention in the logistics industry, with promise of resolving labor shortages, boosting productivity, and enhancing real-time visibility. However, despite the great impact these technologies can have on business results, simply adopting them without careful planning can lead to wasted investment. Maximizing the benefits of digital transformation (DX) requires strong business design and system development expertise, particularly in preparing for operational integration.

Our specialized Logistics Technology (LT) team bridges this gap. Combining an extensive logistics background with deep engineering expertise, our LT unit researches, tests, and develops emerging logistics technologies in our dedicated LT Lab. Once tested and verified, our team assists with customer implementation, creating tailored, state-of-the-art systems that align with each client’s specific business, product, and industry requirements.

We have steadily accumulated practical, hands-on experience in logistics DX and robotics through implementation in our own distribution centers. We introduced two “Autostore” robot storage systems in our Yokohama Kanazawa center, which mainly provides 3PL services for e-commerce business, resulting in labor and space savings at the distribution site.

Our Saitama Logistics Center features a shelf transport robot that reduces the walking distance of picking staff. At the Kanto Logistics Center, we have adopted a robot sorter for more efficient last mile operations. This system is equipped to respond to future trends and volume fluctuations by creating a flexible layout that can adapt to a greater or lesser number of robots. In addition, we are accelerating the use of robotics at other logistics sites, including the use of AGVs (automated guided vehicles) for electronic parts logistics within the premises of our Yokohama Logistics Center.

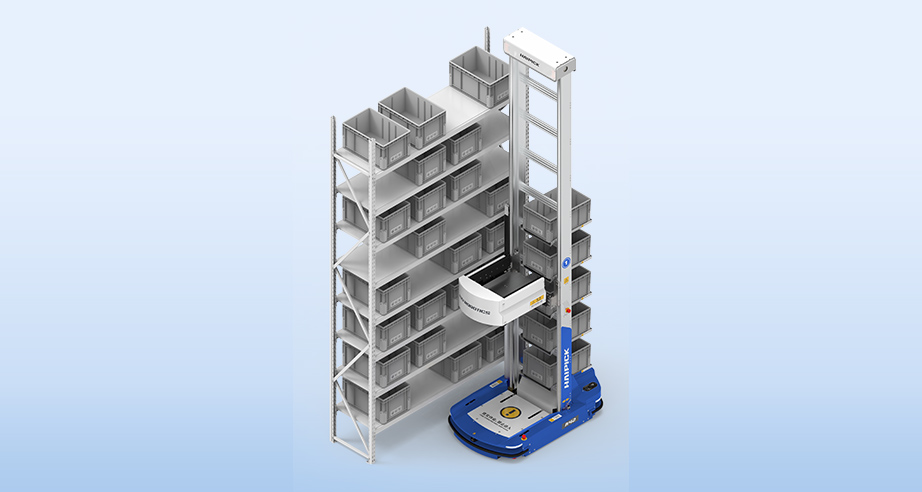

In the future, we are also planning to introduce picking assistance robots (AMR) and high-rise automated case handling robots.

In 2022 we opened a dedicated laboratory with the aim of sharing the knowledge accumulated by each company across the group, accelerating the utilization of ever-evolving cutting-edge LT, and achieving stable operation as soon as possible.

There are a wide range of activities carried out at this facility, including functional evaluation of various solutions, collection of empirical data and effectiveness evaluation of warehouse management systems (WMS) and linked solutions, improvements to manufacturers, and feedback of improvement proposals.

We are currently conducting verification work on a solution for the SBS Group’s EC dedicated center, which will begin operations soon. In addition, we have created an environment where product order information from existing and new customers who are considering implementing SBS’s robot solutions can be transferred to actual robot solutions and tested.

At SBS Group, the LT Planning Department, which brings together LT specialists from each company, will continue to promote verification work and provide continuous and stable logistics services.

The robot takes in and out the container that is stored at high density in the equipment. Multiple robots (electric trolleys) running on a grid (posts and beams) assembled in a grid pattern pull up the bins (dedicated containers) stored in the grid and transport them to the port (picking station). At the port, the staff picks things out of the transported container (picking) and packs things in the container (replenishment).

A robot (automated guided vehicle) that travels on the floor of a distribution facility sneaks under the shelves, lifts the shelves, and carries them to the place where the work staff is located. As the work staff stores things on the shelves brought to the front of the robot and picks things from the shelves, walking does not occur in principle. There is no need to worry about mistaken storage or picking shelves, and work accuracy is improved.

When an item (product) is placed on a tray on a robot (automatic guided vehicle), the robot automatically sorts the product by tilting the tray after self-propelling to the pre-registered chute (frontage). In the case of manual sorting, the work staff needs to walk to each shoot, whereas in the robot sorter, the robot runs by itself and sorts the products by sowing, so speedy processing and workload reduction can be realized.

A transport trolley that runs without human intervention. By utilizing it for the movement of goods in the distribution center, labor saving and labor saving can be realized. It has been introduced at manufacturing sites such as factories, but in recent years it has been introduced at distribution sites for the purpose of reducing the work load and eliminating labor shortages.

A mechanism in which a picking cart (trolley) self-propells and moves to the rack where the products to be picked are stored. When the work staff picks the product from the arrival point (location) of the self-propelled cart and puts it in the cart, the cart moves to the next picking point. In conventional cart picking, the work staff had to walk in the area together with the cart, but in AMR, the cart runs on its own, so it is only necessary to assign work staff to each zone.

A mechanism that allows case products stored in the rack to be automatically taken in and out. Since case products placed on the high-rise part of the rack are automatically taken in and out, it is possible to ensure the safety of work at heights compared to manual work using a forklift, and to improve storage efficiency. Since the work such as storage and case picking can be unmanned, it also helps to solve the labor shortage.